3D printing face masks

Here at Welland Medical, we’re glad to have been given the opportunity by Solid Print3D to help in a very small way with the PPE shortage.

We use 3D printers in developing and manufacturing our stoma care products. The printers themselves are supplied by UK company, Solid Print3D.

In March Solid Print3D contacted their customers to ask for help. There were many projects springing up around the country to produce personal protective equipment (PPE) for health and care workers.

Many businesses that had printers wanted to help, but companies like us, who are still manufacturing other vital medical supplies or have limited 3D printing capacity, couldn’t help at scale.

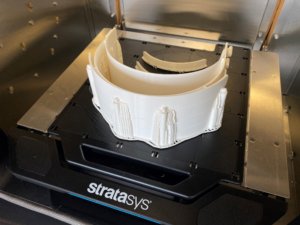

Solid Print3D decided to co-ordinate contributions from their customers, sharing a design from Prusa Research for the headbands needed to produce face shields.

Each headband takes 4 hours to print, and Junior Product Design Engineer Nadeem Hussain is using our extra 3D printing capacity to print 8 headbands every 24 hours, with our printers running overnight.

The headbands are then shipped to Solid Print3D where they are assembling, sterilising and distributing the final face shields. It doesn’t feel like much, but seeing the boxes of headbands arriving at Solid Print3D’s offices, you can see it does add up. In total, they made and distributed 5,793 face shields to front-line medical staff in April.

Thank you to Solid Print3D for taking the initiative, to Prusa for sharing their Rc3 headband design, to Nadeem for getting the headbands printed and shipped from Welland Medical, and to the hundreds of other UK companies working to protect our carers and health professionals.